Quality Control

The high quality of our activated carbon is our trademark. Due to our structured quality controls, we can supply our products with consistent properties.

Monitoring the qualitative properties start as soon as we receive the raw materials. Each delivery of charcoal is thoroughly investigated by our best-trained laboratory employees using a sample. If the composition does not correspond to our specifications, the carbon is not processed. The sugar-water based binding agent is also reviewed.

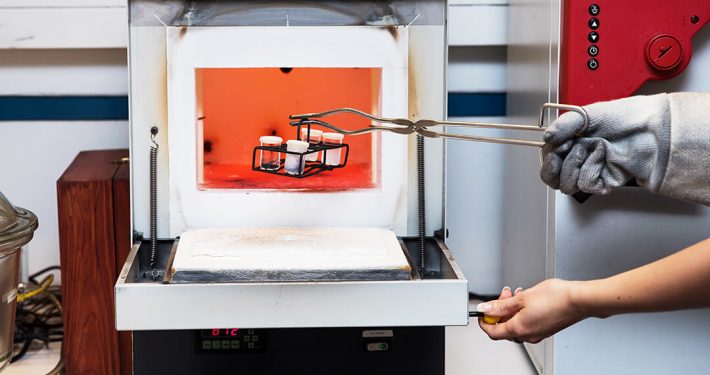

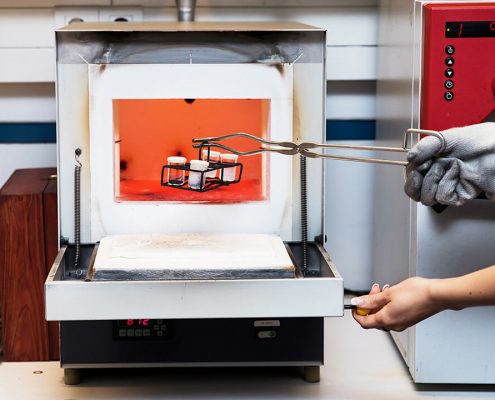

Modern laboratory – Highest quality

The modern laboratory equipment in-house allows the intermediate products in the production process to be analysed and for changes in the production properties to be recognised early on. The processes for production can therefore be controlled, so that the quality of the end product is always guaranteed to meet the required product properties.

A final inspection of the manufactured goods means that for you, as a customer, the quality of every batch of our activated carbon is analysed, and is only dispatched after quality approval.